SG 3.4-145 for the Indian market

Onshore wind turbine

The new variant of Siemens Gamesa’s top performing 3.X platform, the SG 3.4-145 wind turbine is designed to maximize the Annual Energy Production in its projects. Its addition to our portfolio is a clear response to the needs and expectations of the wind energy developers and investors. The SG 3.4-145 is optimized to deliver the lowest Levelized Cost of Energy (LCoE), through a balance of performance, minimization of BoP costs, and efficiency in the WTG design.

Would you like to know more about the SG 3.4-145? Are you interested in partnering up with Siemens Gamesa? Please contact us!

marketingindia@siemensgamesa.com | comercial_consultas@siemensgamesa.com- Optimized design for low wind conditions

- Benchmark solution with high capacity factor

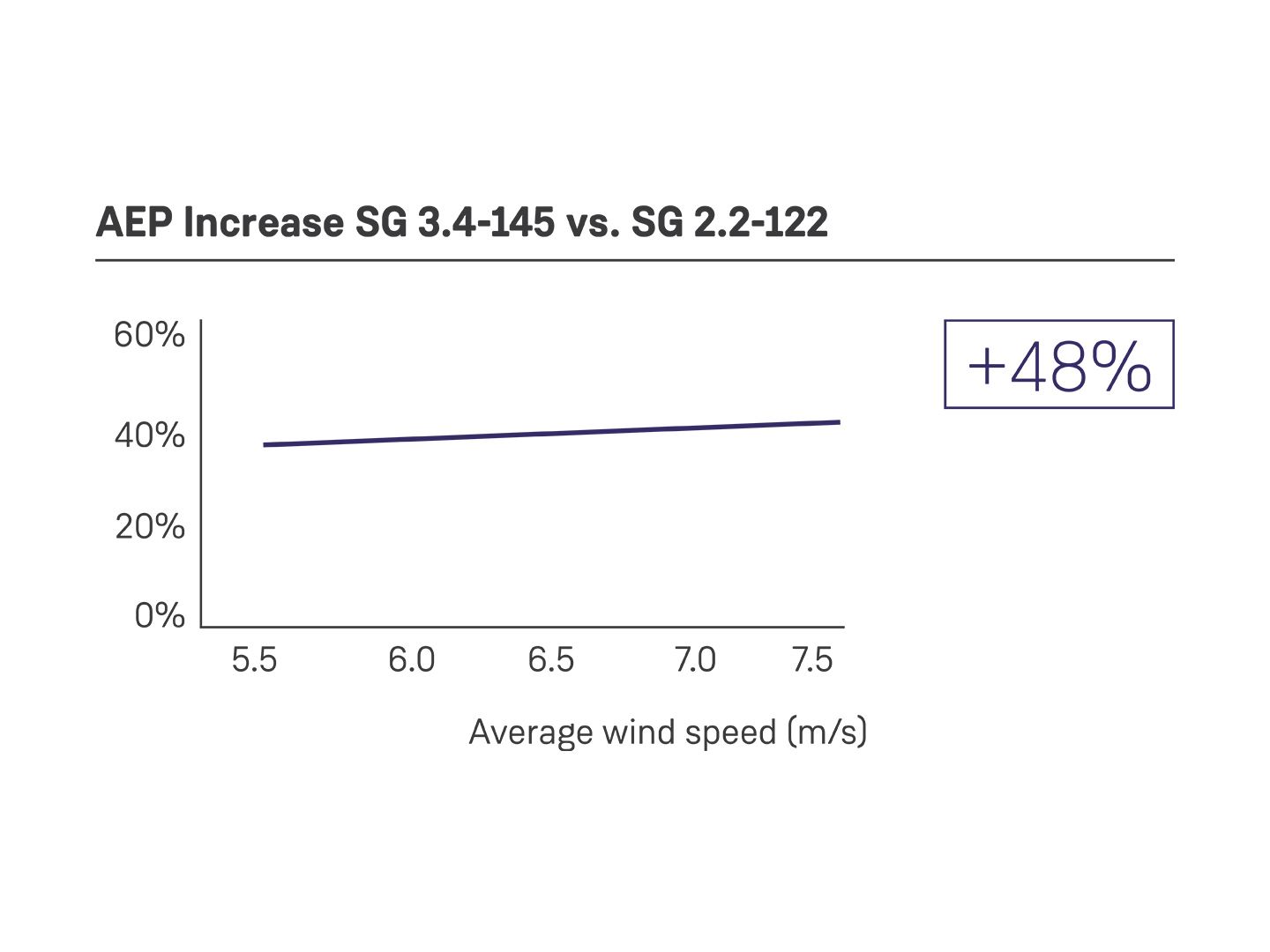

- 48% more AEP than the previous SG 2.2-122

- Up to 3.6 MW with flexible rating strategy

For low and medium wind conditions

| Model | Rotor Diam. | Wind type |

|---|---|---|

| SG 5.0-145 | 145 m | For medium winds |

| SG 6.6-170 | 170 m | For low and medium winds |

| General details | |

|---|---|

| Rated power | 3.465 MW |

| IEC class | IEC III/S |

| Flexible Power rating | 3.0-5.0 MW |

| Control | Pitch and variable speed |

| Standard operating temperature | Range from 0ºC to 45ºC (with de-rating) |

| Rotor | |

|---|---|

| Diameter | 145 m |

| Swept area | 16,513 m² |

| Power density | 209.8 W/m² |

| Blades | |

|---|---|

| Length | 71 m |

| Airfoils | Siemens Gamesa |

| Material | Fiberglass reinforced with epoxy resin |

| Tower | |

|---|---|

| Type | Multiple technologies available |

| Height | 127.5 m and site-specific |

| Gearbox | |

|---|---|

| Type | 3 stages |

| Generator | |

|---|---|

| Type | Doubly-fed induction machine |

| Voltage | 690 V AC |

| Frequency | 50 Hz |

| Protection class | IP 54 |

| Power factor | 0.95 CAP-0.95 IND throughout the power range (1) |

(1) Power factor at generator-output terminals, on low voltage side before transformer input terminals.

The solutions we provide are driven by the benefits they deliver. This applies as much to our pursuit of absolute safety as to maximizing your return. Whether by inventing a new technology, evolving an existing product, or simply finding a smarter way of working, we strive to lower costs and raise returns on investments.

Our experts are on hand to help with any questions you have. Email us, or log in to our customer portal. Here you’ll be able to monitor configuration, production, and agreements for your wind power plants, and find relevant news from Siemens Gamesa Renewable Energy.