Environment information

A green leader

Please reach out to our expert team for more information about Siemens Gamesa’s commitment towards the environment.

info@siemensgamesa.com

Preserving the environment is one of our guiding principles. Siemens Gamesa has established several policies that outline our obligatory and voluntary commitments to protect and enhance the environment.

These policies address different aspects of environmental protection appropriate to the context of our business, including the nature, scale and environmental impacts of our operations, products and services, in addition to the interests of our stakeholders.

Our policies are regularly reviewed and apply globally, covering our entire operations. They apply to all Siemens Gamesa employees and, furthermore, are relevant to our business partners.

Siemens Gamesa is deeply committed to generating a positive effect on the environment, providing clean solutions to power our homes, schools, hospitals and keeping us moving wherever we are – from the largest cities to the most remote corners of the planet. To this end, the company has outlined our way to contribute a decarbonized economy, with the goal of reaching net-zero emissions by 2040. This includes emissions produced by the company’s whole value chain. Previously, the net-zero target was 2050.

- Energy reduction and efficiency measures

- Electricity supply from renewable sources

- Green mobility and fleet plan

- Offseting projects for non-avoidable emissions

- Employee awareness campaigns and idea management

- Increased engagement across the value chain

Siemens Gamesa became carbon neutral in 2019 – five years ahead of schedule. In 2020, the company became powered by 100% renewable energy and had the SBTi (Science Based Targets Initiative) verify that our emission reduction targets until 2025 are meeting the most ambitious 1.5°C scenario. To document our progress, we publish our Greenhouse Gas Emissions report annually which is externally verified according to the requirements described in ISO 14064-1:2018.

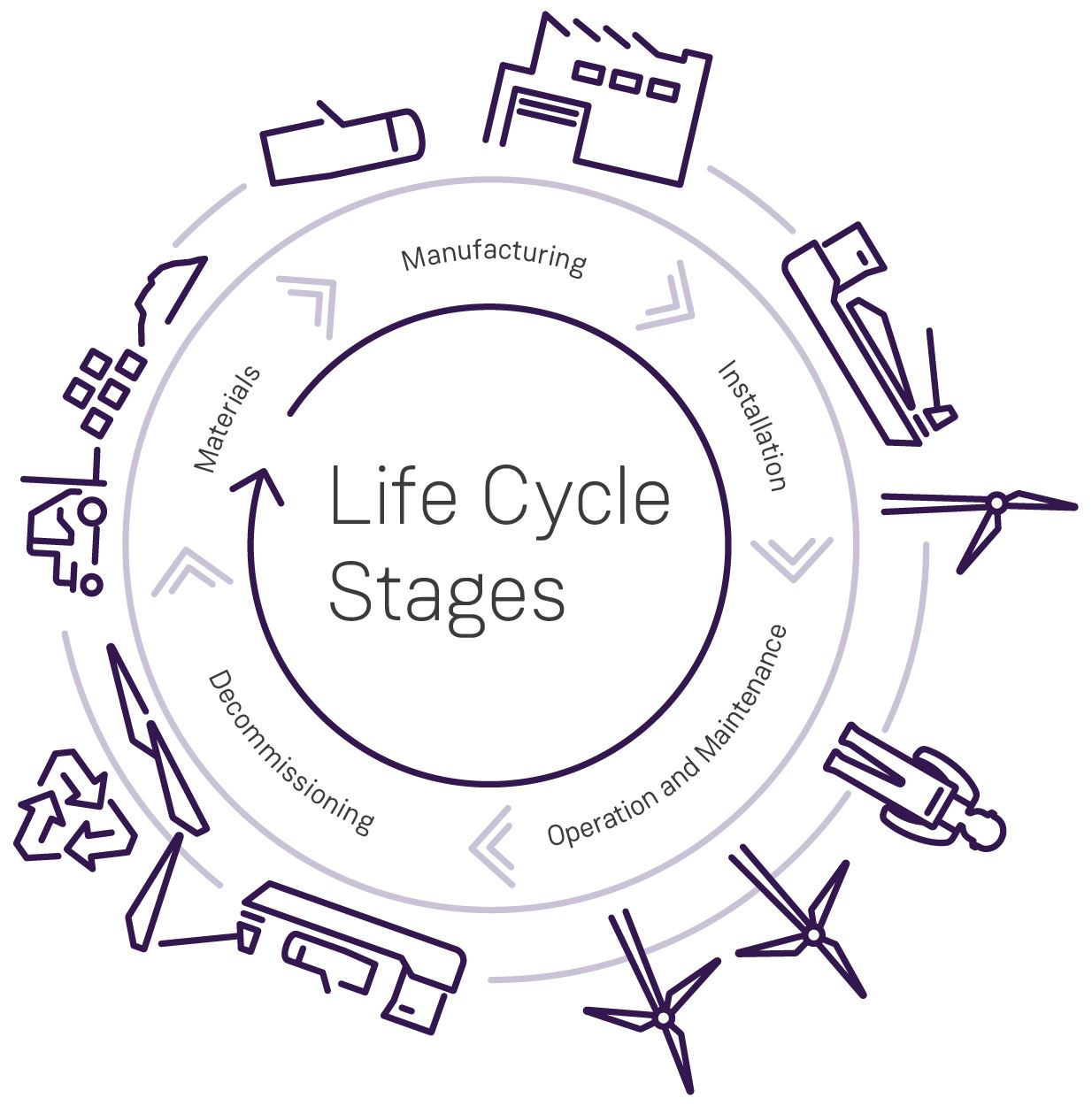

Siemens Gamesa calculates the environmental footprint of wind turbines using Life Cycle Assessments (LCA) – a method that assesses our product’s environmental impact over its entire life cycle, from raw material extraction and manufacturing, through transport, installation and operation, to decommissioning and recycling. We present the LCA results using Environmental Product Declarations (EPDs).

Our LCAs and EPDs are made in accordance with the ISO 14040, 14021 and 14025 series of standards and applicable Product Category Rules (PCRs). Many of these can be found in The International EPD® System (search for Siemens Gamesa).

Our most significant efforts include:

- Reducing waste, energy and water

- Reducing and substituting materials, including chemicals

- Optimizing packaging and logistics

- Improving capacity factors for higher energy outputs

- Applying remote diagnostics to increase availability

- Adopting alternative technologies for installation and service vessels

- Reducing service time frequencies

- Protecting wildlife with integrated SCADA control systems

- Offering component upgrades and spare parts to extend turbine lifetime

- Repairing and refurbishing components

- Designing modular components to optimize dismantling and waste treatment

- Seeking alternative materials for high recyclability

Forging the future of wind

We are pursuing an ambitious target to reach net-zero CO2 emissions by 2040. The use of GreenerTowers alone will reduce total CO2 equivalent emissions from the turbine by an impressive 20%. This is the next important milestone on our journey to deliver even more sustainable wind energy.

Ensuring a sustainable production process with less environmental impact will be of great importance, given an expected rise in the number of installations and in the size of the turbines in coming years.

GreenerTower – The next step toward net-zero

Siemens Gamesa’s new GreenerTower focuses on achieving significant CO2 equivalent reductions in the steel plate production for steel towers. Today, the average CO2 equivalent emission on steel is 1.91 tons. For our GreenerTower, a maximum of 0.7t of CO2 equivalent emissions are permitted per ton of steel. This means a CO2 reduction on the tower steel plates of at least 63% compared to conventional steel production.

The GreenerTower is based on the exact same design as a standard tower. The only difference is within the steel plate production, where CO2 emissions are significantly reduced compared to conventional steelmaking. GreenerTowers will initially be sold as an option for both Offshore and Onshore turbines for projects to be installed from 2024 and onwards.

There are several ways to achieve CO2 reduction in the production of steel, including the following:

- Use of less energy intensive steel manufacturing processes.

- Increased use of scrap steel.

- Increased use of CO2 neutral energy sources.

While it is critical to hit net-zero targets and provide affordable, clean energy to the world, the rollout of clean energy must be done in a sustainable way, actively avoiding environmental damage and supporting the circular economy with a reduced reliance on resources.

The wind industry is still relatively young and is aware of the responsibility it holds of finding a sustainable way to deal with wind turbine components at the end of their life cycle. Increasing the recyclability of the wind components is high on our agenda, and we are committed to producing 100% recyclable turbines by 2040.

Previously, the industry has not been able to recycle wind turbine blades upon decommissioning, resulting in blades ending up as landfill. Now, thanks to our pioneering RecyclableBlade technology, the materials from our RecyclableBlade can be recycled and reused in other industries to the benefit of future generations.

Our RecyclableBlade is a simple, and robust solution, developed through technological ingenuity. The only change to the blade production process is our new resin. This means that scaling up production and rolling out this recyclable product is not only possible, it is already a reality! The first blades have already been produced in 2021.

We focus both on finding ways to demonstrate commercial value chains for thermoset rotor blades that are already installed in our fleet as well as investigating new materials with enhanced circularity for our future blades.

There are various regulatory and voluntary instruments that ensure Siemens Gamesa’s wind projects are constructed and serviced in a way that allows for co-existence, and often a net-positive biodiversity impact. This is in line with SDG 14 and SDG 15, protecting life below water and on land, respectively.

The Siemens Gamesa Corporate Commitment to Biodiversity considers and integrates the main current biodiversity frameworks, initiatives and tendencies at an international level (Nature-Positive Global Goal for Nature). With this commitment, Siemens Gamesa ensures that its biodiversity management and performance will be at the forefront of the group of businesses and organizations that are establishing ambitions and commitments on the topic.

As per the Indian Environmental statutory norms, every organization which generates bio-medical waste data should display its waste disposal data in its company website for public view. This mandate come under the preview of The Bio-Medical Waste Management Rules,2016 & The Environment (Protection) Act, 1986. In this context Siemens Gamesa Renewable Power Private Limited, a company registered under the Indian law is manded to display the bio-medical waste disposal data for its manufacturing plants in India: Nacelle Manufacturing Plant in Tamil Nadu and Blade Manufacturing Plant in Andhra Pradesh.