Pushing offshore to a new dimension

Madrid / 17 July 2020

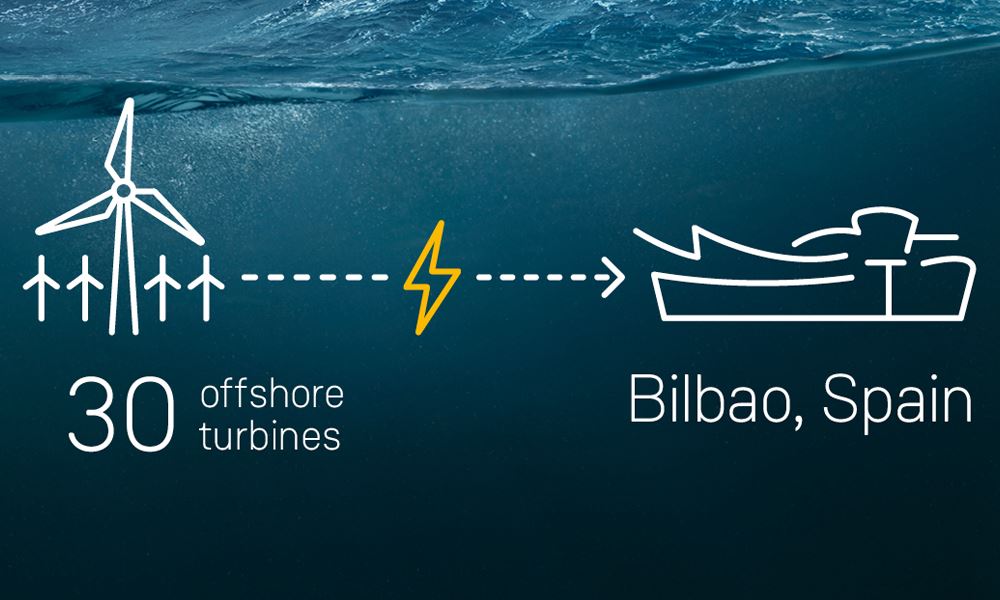

Titan, giant, colossus, gargantuan scale, monumental dimensions. Describing Siemens Gamesa’s new offshore wind turbine is no easy job. With an unprecedented energy capacity of 14 MW and rotor of 222 meters, the launch of the turbine amazed the market. In just over a month, it accumulated 4.3 GW of conditional orders with different customers in markets as diverse as Taiwan, the United States, and the United Kingdom.

To explain some of the key insights of the SG 14-222 DD launch, we invited Peter Esmann, Senior Product Manager, and Sidse Legaard Jensen, Commercial Product Manager for a brief chat. Both have been directly involved in the launch towards customers and ensuring that the business case remains positive for Siemens Gamesa – even in a challenging, cost-focused environment. We’ve asked them to analyze the keys to the product’s development, in which over 190 employees from the company have participated.

Q: What does this launch mean for Siemens Gamesa?

Sidse: This launch strengthens Siemens Gamesa’s position at the forefront of the offshore wind industry. Of that there is no question. We pioneered the offshore wind market with the first project back in 1991, we developed it, and have pushed the entire industry forward to a new dimension. Offshore plays a key role in the present and the future of the energy transition: with this 14 MW turbine, we have the most competitive product ready in time for the huge projects that are being tendered and auctioned now, with installation set for the mid-2020s across the world.

A: The launch of the SG 14-222 DD provides our customers with an increase of more than 25% Annual Energy Production (AEP) compared to the predecessor, improving the business case of our customers significantly. Of course, bigger is not automatically better, so we have had great focus on keeping weight and loads down to the benefit of our customers’ balance-of-plant costs. In order to provide the best possible business case for our customers, we consider everything from the first wind gust touching the blade and until the power is ready in the onshore cables.

Q: You mentioned large customer projects, where will those projects be installed?

A: The big traditional European markets lead the offshore market, especially UK, Germany, and The Netherlands. We expect strong growth in Asia-Pacific (APAC), starting with Taiwan, followed by Japan and Korea, and then there’s the US. These markets will take off in the mid-20s.

Q: Let’s talk about dates. After the launch in May 2020, what are the next key dates for this product?

A: The installation of the prototype will start by the end of 2021 in Østerild, Denmark. The blades for the prototype will come from our factory in Aalborg, Denmark, and the nacelle will be produced in Brande, Denmark. This is the same as its predecessor, which was successfully installed and commissioned early this year. We are looking forward to utilizing our new blade test stand in Aalborg to test these huge blades. We plan to start serial production by the end of 2023 so that we can install the first commercial project by Spring 2024.

A: Of course. This control feature can be applied to any existing offshore wind power plant. But it’s especially interesting for wind power plants equipped with the new SG 14-222 DD turbines. The larger the rotor is, the more Wake Adapt has the opportunity to create even more value. Basically, the larger the wake effects are in the wind power plant, the more benefit our customers will gain from applying the Wake Adapt feature.

The size of the turbine is revolutionary, yes, but the technology is based on a solid foundation of five previous generations of Direct Drive machines

Esmann: We had to rethink the product launch strategy, and eliminate an in-person launch. Despite the COVID-19 outbreak, we successfully managed the launch in the best possible way, and maximized the use of digital platforms to reach all of our stakeholders: customers, journalists, employees, and more.

A: Selling a turbine even before the prototype is up requires a lot of trust from our customers but that trust is helped by the fact that we have already installed 1,000 offshore Direct Drive turbines and sold an additional 1,000 turbines. This means a lot. By the time we install our first project, there will be more than 2,000 Siemens Gamesa offshore Direct Drive turbines spinning out at sea.

A: The size of the turbine is revolutionary, yes, but the technology is based on a solid foundation of five previous generations of Direct Drive machines. The real challenge is that we have managed to scale it up to almost 15 MW and keep the weight of all the components low, from blade to the tower and foundation. As you know, Siemens Gamesa IntegralBlades® have a mass advantage – for the big blades, we estimate a 3-4% lower weight compared to those of other manufacturers, which are glued together from two pieces.

Q: The turbine can be adjusted to produce 15 MW with Power Boost. Can you explain how?

A: The Power Boost function is a wind turbine control feature that increases (boosts) power based on real-time monitoring of the site-specific conditions. For turbines equipped with Power Boost, this functionality is always active. However, if for example the wind speed reaches storm levels, or the turbulence level exceeds a certain limit, Power Boost is deactivated, and the turbine returns to normal power. What we have seen in our fleet analysis is that the Power Boost feature is active more than 98% of the available time, and thus ready to produce up to 15 MW power for this turbine.

Q: As you know, the huge scale of the offshore turbines always takes the headlines. Blades larger than the Statue of Liberty, turbines taller than the pyramids of Egypt. How tall is this turbine?

A: This will always depend on the site requirements. With a 25-meter clearance between the tip of the blade and the water line, the tip height reaches 247 meters. But if a specific project needs a higher clearance, let’s say 50 meters for example, then the tower would have to be longer and the tip height would reach 272 meters.

Esmann: From a pure technical perspective, the issue is not to make the turbines larger. We can foresee even larger megawatt turbines becoming commercially relevant as we approach the end of the decade. Since factories and the suppliers have come closer to ports, land transport is also no longer a key supply chain challenge. The largest technical challenge as we see it now lies with installation vessels, as they must lift consistently longer and heavier towers in one go. There are only a handful of installation vessels in the world that can do that for the turbines in this class.

The solution in the future might come for example, by lifting the towers in two go’s or investing in larger vessels. We’ll see; in the end it depends on the business case.

Sidse: The big question that any manufacturer should pose is not technical but commercial: is there a solid business case behind the design of a massive wind turbine? You need to carefully weigh up all the risks. Like with ships or aircraft, there comes a point where increasing size is not economically viable anymore. This however does not mean that turbine developments will then stop, but instead that the advances will likely focus even more on efficiency. We will as an industry always continue to strive for excellence.