Wind class

I, S

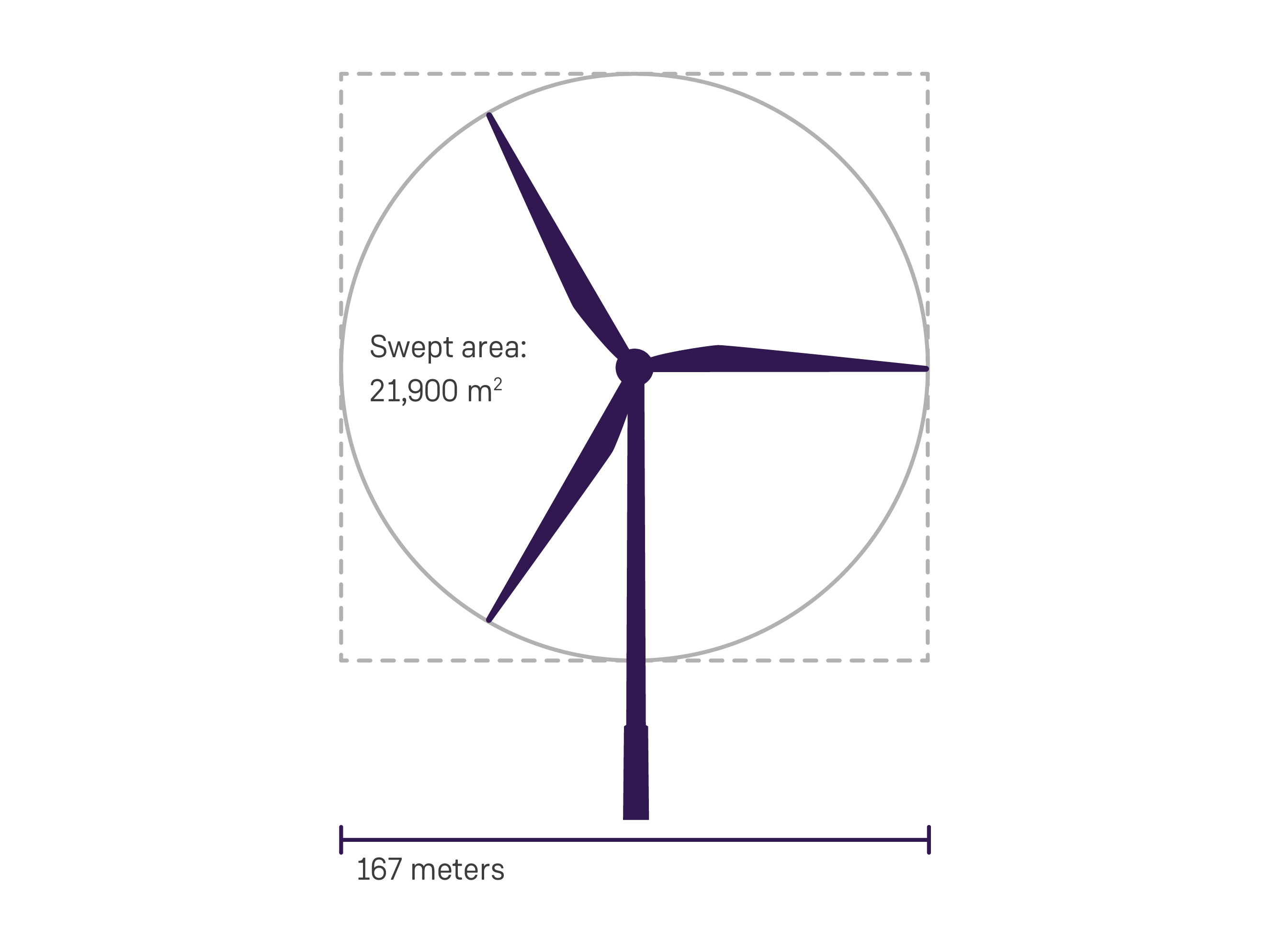

Rotor diameter

167 m

Serial production

2019

Nominal power

8.0 MW