From Soria to Atacama, the long trip from the nacelles capital

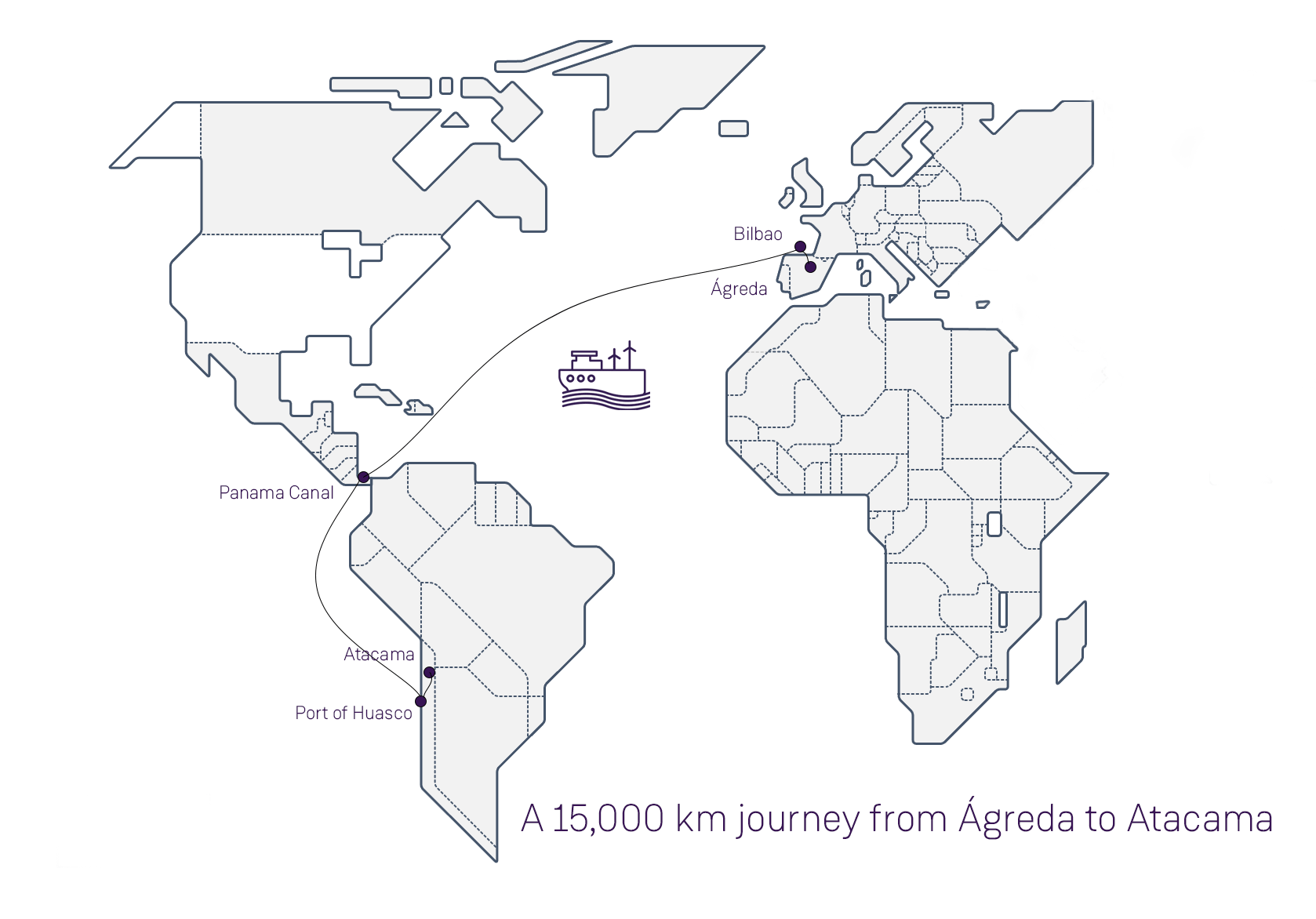

Ágreda, a village of around 3,000 inhabitants in Soria, in the middle of Spain, is one of the hubs for Siemens Gamesa's global wind turbine production. This is where a nacelle assembly plant is located. From here, the nacelles, which are the heart of a turbine, are transported halfway around the world via the Port of Bilbao. The last nacelles assembled in the factory are already on their way to the Port of Huasco, Chile, to be installed in the Atacama region, a journey that will last almost two months and cover over 15,000 kilometres.

Siemens Gamesa has six nacelle plants worldwide, but Ágreda is the only one, along with Tianjin, in China, that produces for overseas markets, making the Spanish plant a true export hub and, in the wind industry sector, one of the most important nacelle plants in Europe.

Apart from the models currently produced at the Ágreda plant, serial production of the nacelles for Siemens Gamesa's new SG 5.X platform, among the most powerful in the world, will soon be added.

The nacelle prototype has been manufactured and tested in Ágreda and serial production will begin in the coming months.

The plant has already been assigned several of the projects signed with the new platform in Sweden.

Siemens Gamesa's managing director for Spain, Enrique Pedrosa, points out that "activity in Ágreda is secured thanks to the SG 5.X projects. The mass production of these new wind turbines will also boost the manufacture of gearboxes and electrical components that are produced in the eight plants we have in Spain, which employ more than 1,000 people."

The challenge of constructing a wind farm does not end there. A wind farm is a puzzle that needs to be solved well in advance.

The case of Cabo Leones III is a good example: the nacelles arrive from Spain, while the towers and blades are shipped from China and India.

It is important that all of this arrives on time so that the wind farm can be built up according to the schedule.

The global presence of Siemens Gamesa, with wind farms and factories all over the world, means that the components for each wind farm, as in the case of Cabo Leones III, usually come from different countries and continents. This allows for greater flexibility in planning and execution, but also requires constant monitoring of the projects.

Cabo Leones III is undoubtedly a project that represents like no other the enormous logistical challenge behind each wind farm, from production to assembly of the components, including transport, and also the importance that Siemens Gamesa's plants in Spain have in the production of turbines around the world.