Greener, cheaper and more efficient service operations with a new type of vessel

Madrid / 29 June 2021

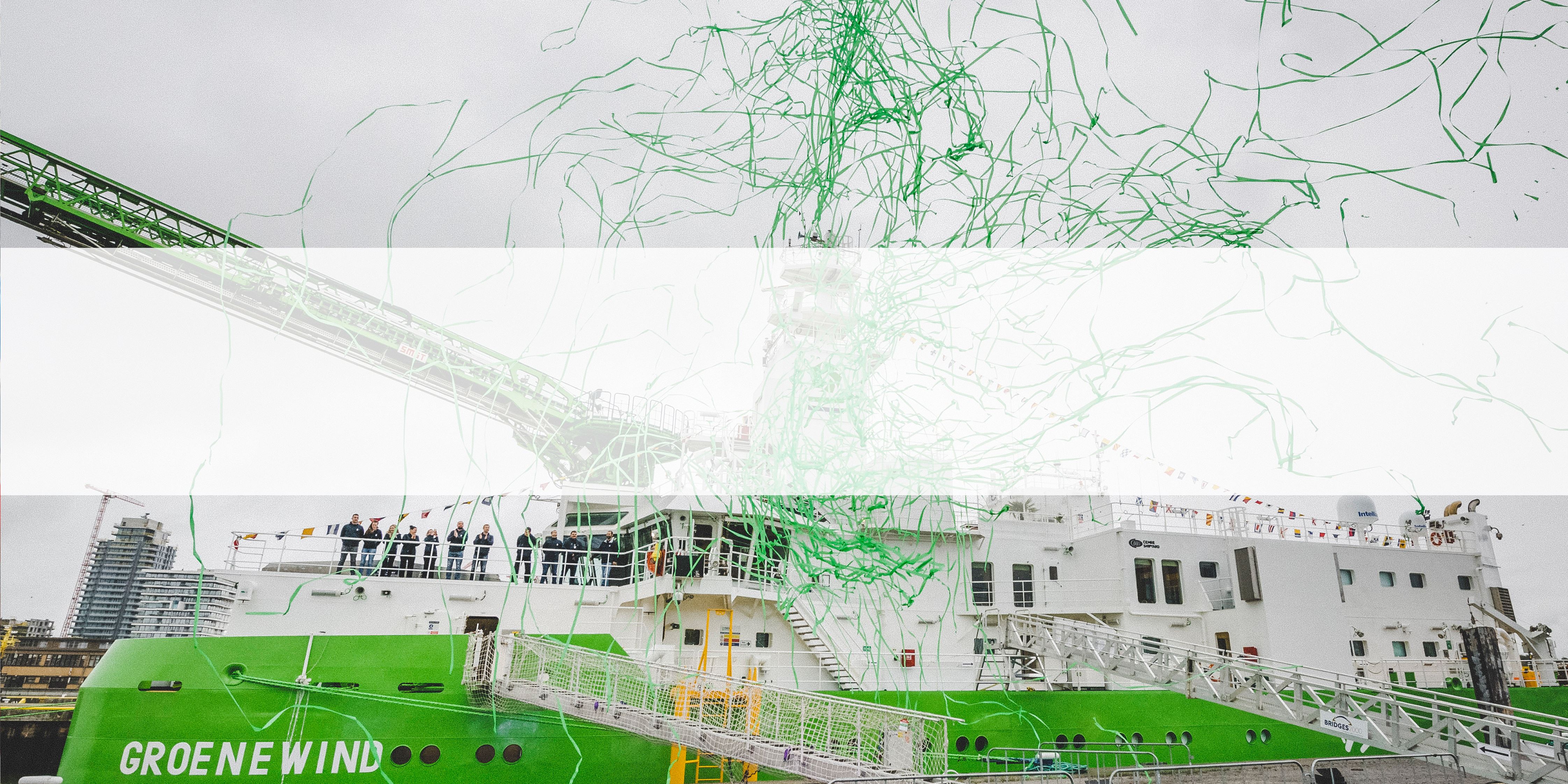

The new vessel ‘Groenewind’, a first of its kind in the offshore service arena, will be deployed by Siemens Gamesa forthe next 17 years, one of the most extensivecharters in the company's history, to service 100 turbines in Belgium. With this vessel, Siemens Gamesa will be able to provide further optimized, competitive, green and safe maintenance solutions.

A total of 100 Siemens Gamesa turbines are generating electricity in the Belgian Rentel and SeaMade offshore wind power plants (a combination of the Seastar and Mermaid projects). The combined 796 MW of capacity can produce enough sustainable energy to power an incredible 785,000 Belgian homes annually.

Siemens Gamesa is now servicing these turbines, and thus responsible for ensuring they function to their optimum – effectively, reliably and safely. But how do we make this happen logistically, when you cannot just drive up to the turbines with a van?

"We have called on three decades of wind power expertise to charter a new type of vessel for the maintenance of these projects, which will make up the largest wind power installation in Belgium. With the vessel ‘Groenewind’, a first of its kind in the offshore segment, we will be able to provide further optimized, competitive, green and safe maintenance solutions,” explains Rene Wigmans, Head of Offshore Service Logistics Siemens Gamesa.

"We have called on three decades of wind power expertise to charter a new type of vessel for the maintenance of these projects, which will make up the largest wind power installation in Belgium. With the vessel ‘Groenewind’, a first of its kind in the offshore segment, we will be able to provide further optimized, competitive, green and safe maintenance solutions,” explains Rene Wigmans, Head of Offshore Service Logistics Siemens Gamesa.

This new kind of vessel helps us to drive down the cost of green energy:

- The vessel is smaller and lighter than typical Service Operation Vessels (SOVs) and, thus, more sustainable: it needs less fuel to operate and fewer materials for its construction.

- It is the first SOV with a SWATH (Small Waterplane Area Twin Hull) design, instead os monohull. This ensures low wave impact on vessel - roll and pitch - movemnts when approaching wind turbines.

- It is the only SOV with a motion compensated gangway in the bow, which enables higher range of gangway angles and provides the vessel with full flexibility to maximize the workability by always transferring in head seas.

- It can hold its position in rough seas, but at the same time operate with lower fuel consumption. An impressive reduction of up to 50% in fuel consumption can be achieved compared to a monohull SOV.

"In summary, the combination of all these characteristics increases workability and allows us to use a smaller vessel that maintains the workability of a bigger monohull vessel; thus, driving down the cost of wind farm maintenance and in a more environmetally friendly manner," explains Fernando Sánchez, Principal Naval Architect at Siemens Gamesa