Remote Services for wind farms

Digital expertise for better outcome

Our remote diagnostics approach is unique, advanced and deeply implemented: We combine knowledge on turbine design and technology, applying historical data and machine learning capabilities to foresee component behaviours as no other supplier can.

This ensures predictive maintenance capabilities to enable effective maintenance planning and execution to keep operational expenditures within control.

Are you interested in our digital and diagnostic service solutions? Please contact our service team.

info@siemensgamesa.com- We maintain the industry’s largest amount of historical data

- Troubleshooting advice with an accuracy of at least 97 percent

- More than 98 percent of serious component failures is detected in advance

- Resolution of issues can be managed remotely in more than 85 percent of the cases

- Algorithms filter out costly false-positives and insignificant deviations

- Customers achieve higher yield and a remarkable LCoE

All onshore and offshore wind turbines and power plants

| 24/7 Alarm Response |

| Software Version Update |

| Troubleshooting Support |

| Turbine Setup control |

| Vibration Diagnostics |

| Advanced Endpoint Protection |

| SCADA+ Care |

By model-based diagnostics we gather data from around 6,000,000 sensors from turbines worldwide and create 1,500,000 individual digital models out of it. The system flags around 250,000 deviations per year. But which of these positives correspond to real-life faults?

Our algorithms filter out the costly false-positives and insignificant deviations. This drops the count of significant deviations that need to be addressed to approximately 8,000 site visits a year. In fact: we don’t need to follow false-positives and your average turbine needs to be visited less often.

And the implementation won’t stop there: From service technicians reports to analyzing damage parts, it all feeds back into an ever-learning knowledge base supporting all kinds of digital tools.

You can access to the relevant experts for remote support and advice to resolve specific identified incidents. We will provide you with remote support for troubleshooting and for corrective actions.

Our service can be offered in reactive or proactive options.

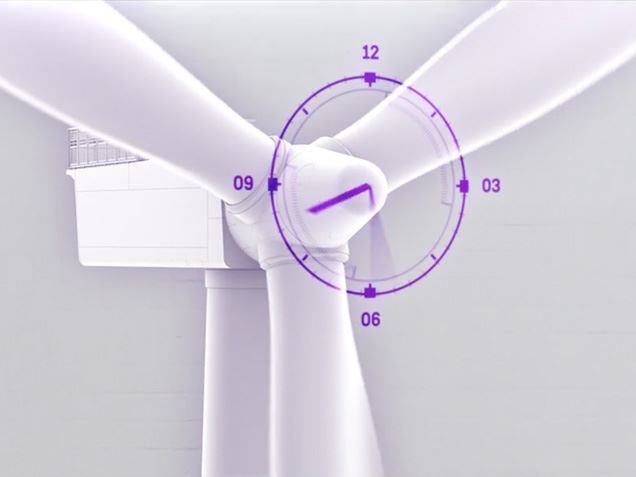

By picking up vibrations on turbine components, sensors can lower the risk of slow- and fast-developing damages by early detection and optimize maintenance strategies – such as automatic turbine shutdown or preventive repair. This helps to save service costs and reduce downtime.

A market leading condition monitoring solution enabling improved detection capabilities on drivetrain components.

With smart use of data and cutting-edge machine learning capabilities or condition monitoring solution make early detection up to 3 years in advance on fast and slow developing damages.

Our service can be offered in a passive and active mode to suit your service requirements.