Decarbonizing the supply chain

The next step on our journey to net zero emissions by 2050

Hamburg / 18 December 2020

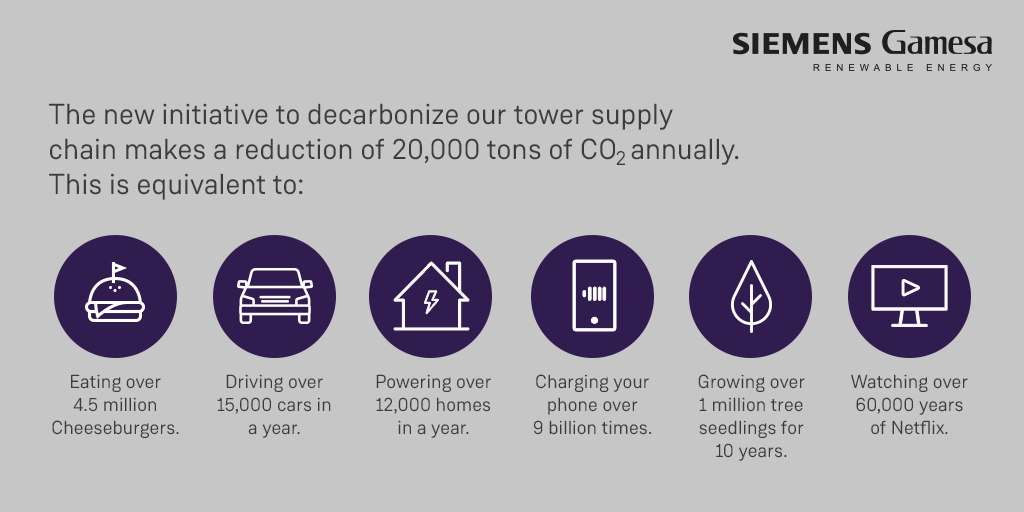

Over the course of 2020 Siemens Gamesa has recorded several crucial decarbonization successes - becoming carbon neutral or switching to 100% electricity from renewable sources to name just a few. But we are committed to going further: reducing indirect emissions in our supply chain is a vital step on our journey to net-zero emissions by 2050. The production of towers is a major source of carbon emissions worldwide and therefore a great place to start. Siemens Gamesa deployed a decarbonization project for the tower supply chain with promising first results: a reduction of 20,000 tons of CO2 emissions annually, approximately 20% of the emissions generated by its main tower suppliers. Compared with emissions derived from all our activities, this reduction accounts for more than 70% of the company's annual emissions.

But our ambition goes further. To reach our overarching goal of becoming net-zero, reducing our indirect emissions generated in the supply chain is inevitable, as over 80% of the carbon footprint of our wind turbines is linked to the materials used in their manufacturing. To mitigate the supply chain impact, we are working with our suppliers and supporting them on their own decarbonization journey.

“We are reducing the carbon footprint of our own production facilities and offices, but we know that the main challenge going forward will be to reduce emissions in our entire supply chain. The joint program from Tower Operations and Procurement aims at consciously reducing CO2 emissions emitted during the manufacturing process of our products and the required raw materials to have the most sustainable value chain,” Cresten states. “We now have full transparency of where the CO2 emissions occur and how they can be reduced. This allows our suppliers and us to push for the needed change”.

This program, launched in early 2019, stands on three pillars: (i) implementing a transparent annual process to evaluate the sustainability performance of each supplier; (ii) incentivizing suppliers to join the effort in reducing the shared environmental impact by rewarding good performance with a bonus system; (iii) and establishing a collaborative relationship with suppliers by providing education and guidance on sustainable practice.

Partnering with the Procurement department proved to be the driver to bring the tangible results. The decarbonization of manufacturing processes of Siemens Gamesa’s suppliers is becoming a supplier selection criteria. A ‘Sustainability/Greenhouse Gas Emissions’ category is incorporated into the Towers yearly supplier evaluation process and gives the company’s suppliers an opportunity to present their CO2 reduction efforts.

The promising first results of the program have driven a global development of the initiative. Siemens Gamesa has a clear ambition to include the supply chain in its decarbonization efforts and set targets accordingly. “This first pilot program offers lessons learned that can be applied to other areas of the organization, for sure. We are currently expanding this for tower procurement globally, meaning increasing the number of suppliers from 10 to about 40, and will then gradually expand the scope from there across multiple high impact commodities,” says David Anderson and adds, “Clearly, it shows how the commitment of a dedicated team can lead to great results and accelerate our decarbonization efforts to limit global warming to maximum 1.5° Celsius.”

Siemens Gamesa still has a long way to go to reach its ambitious decarbonization goals but is taking firm steps on the road to a low-carbon value chain.